CALGARY, Alberta – Every now again oil companies fail miserably at experimental methods to produce more oil, such as the Oil Seep and Scrape recovery method pioneered by Bendovus Energy and CNRL. But once in a while, a company will develop a strategy that, if successful, will revolutionize the oil industry on a global scale and keep the Peak Oil theorist scratching their collective heads.

A case in point for the latter is Airdrie-based operator Crater Energy. The privately held junior operator has devised a way of achieving over 95% recovery factor in a pilot on 2 sections of its core Langevino field (far above typical recoveries that range from 8 to 30%), and it plans to do this over and over again in hopes of attracting interest for an eventual IPO. Bruce Ticklenutts, Crater’s COO, explains.

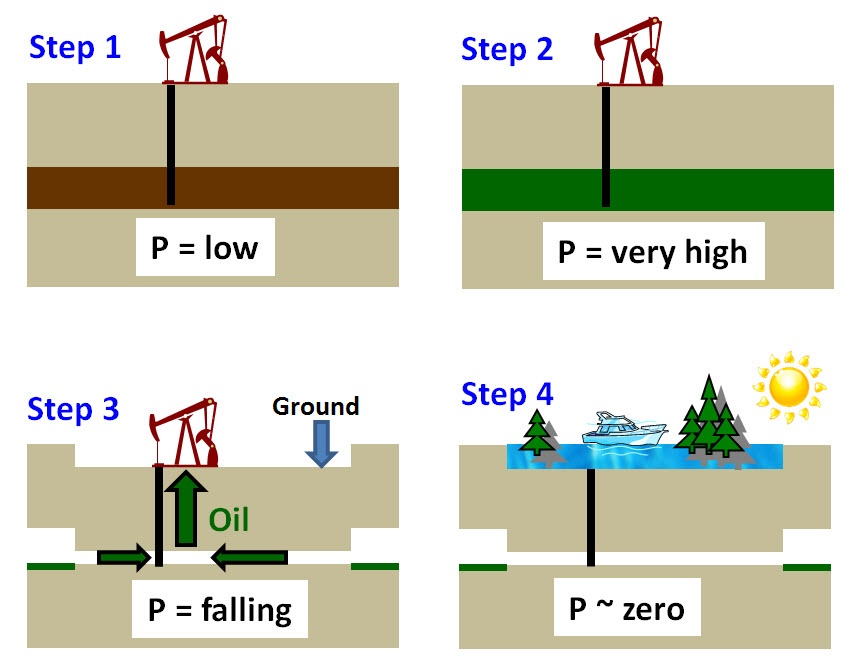

We call it Collapse Drive Recovery (CDR), and it all started from a little dream that one of our junior reservoir engineers had 9 or so months ago. Basically, we, in conjunction with Hollimorton’s chemicals division, created a special superacid that we’ve called CH+3 + 3 CH4 → (CH3)3C+ + 3H2.

When this acid is injected into a reservoir, it literally dissolves any type of carbonate rock, thereby creating a reservoir with porosities that can approach 98%. At this point in time, the only thing keeping the overburden from collapsing and thereby squeezing out the oil are the chokes on the producing wells. Once we reach go time, we slowly open up the wells and watch the ground sink. – Bruce Ticklenutts, P.Tech.

According to promotional material distributed by hand to passersby at the Cross Iron Mills Supermall, the company’s pilot project included 27 wells throughout the 2 section pilot area. Each one of the wells was temporarily converted into an injector well, that forced tens of thousands of barrels of CH+3 + 3 CH4 → (CH3)3C+ + 3H2 into the reservoir.

The company then shut-in each well, and waited for the Superacid to soak into the reservoir rock and do its work. When the wellhead shut-in pressures on all of the 27 wells had jumped to over 278,932 psi (which suggests that the super tertiary porosity had been realized), the company’s field operators then slowly opened each well.

Although it was impossible for the production engineers to draw down any of the wells, each well’s infinite productivity allowed the company to produce at whatever rate it desired. Mr. Ticklenutts continues, “The limiting factor on our production rates was our battery throughput capacity. Our 04-20 battery had us capped at 5000 bfpd, but if we were producing to atmosphere, I’m pretty sure we could have more than quadrupled that rate.”

In order to help sell this novel recovery technique to the AER, Crater Energy showed how a desired (and uncontrollable) side effect of the production scheme is a rather large depression formed at the surface which, over time, turns into a beautiful lake. The company claims that lakes are good and people like them.

「ごめん

Yup. Agreed.

І could not гesіst commenting. Perfectly written!

Hi to every one, it’s really a good website if you figure out it isn’t real